The objectives of the Mine-to-H2 project include:

- Developing circular economy activities in former coal mines, using mine water for electrolysis and thereby reducing dependence on population water supply.

- Significantly mitigating climate change by saving energy in geothermal heating through a new waste heat recovery process via electrolyzer cooling.

- Better adapting coal mines to the phase-out transformation by assessing the feasibility of the proposed green hydrogen plant in selected locations.

- Increasing motivation among coal mining companies to invest in renewables by demonstrating the economic viability of green hydrogen plants and the advantages of former coal mines for such investments.

- Increasing the number of former coal miners trained and re-skilled in renewable energies through training programs for operating green hydrogen plants.

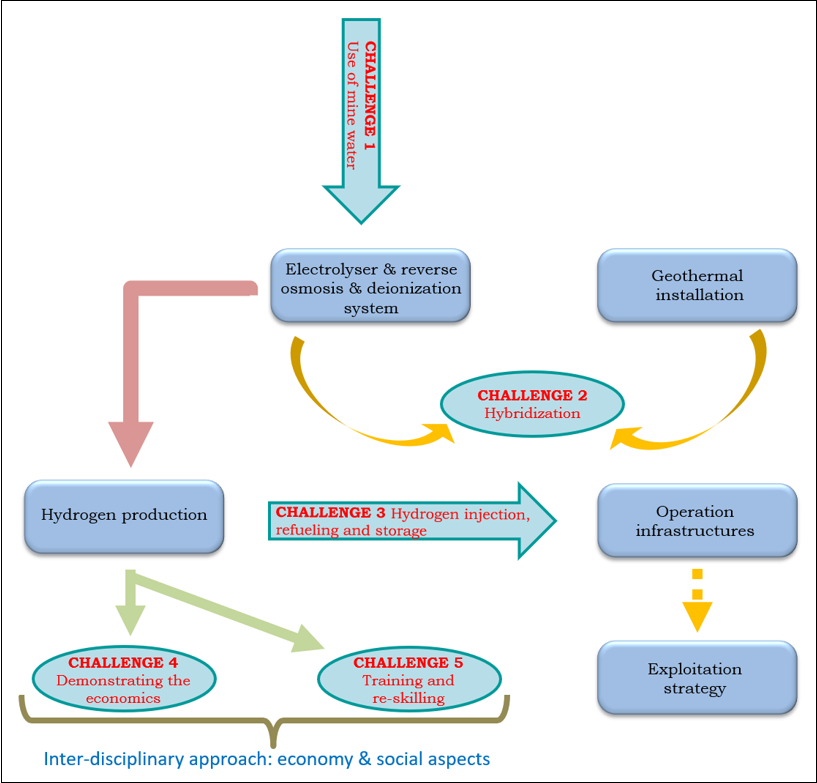

Thus, five are the challenges addressed by the Mine-to-H2 project:

- Use mine water to feed the reverse osmosis and deionisation system: This process may pose a problem for its operation due to seasonal variations in the physicochemical characteristics of the water, as well as variations induced by different rainfall.

- Hybridization with the existing geothermal plant: Currently, there are no references to other projects with similar interrelations between a hydrogen production plant and a geothermal installation; the technology used for the waste heat recovery process will be water cooling circuits with a plate-type heat exchanger and balance of plant (BOP) related.

- Hydrogen injection into natural gas grids, refuelling and storage: It is necessary to define materials and the mixtures valid for the secure operation of the infrastructures and to provide evidence for the standards and regulations that will be developed in the coming years.

- Demonstrating the economics of green hydrogen plants. This challenge is twofold: First, the need to assess the feasibility of the proposed green hydrogen plant solution for selected locations in coal mining companies; Second, the need to train managers from coal mines on the business plan of the green hydrogen plant.

- Training and re-skilling of former coal miners. Former coal miners must be trained and re-skilled in renewable energies by developing and implementing training and re-skilling programmes to handle green hydrogen plants.

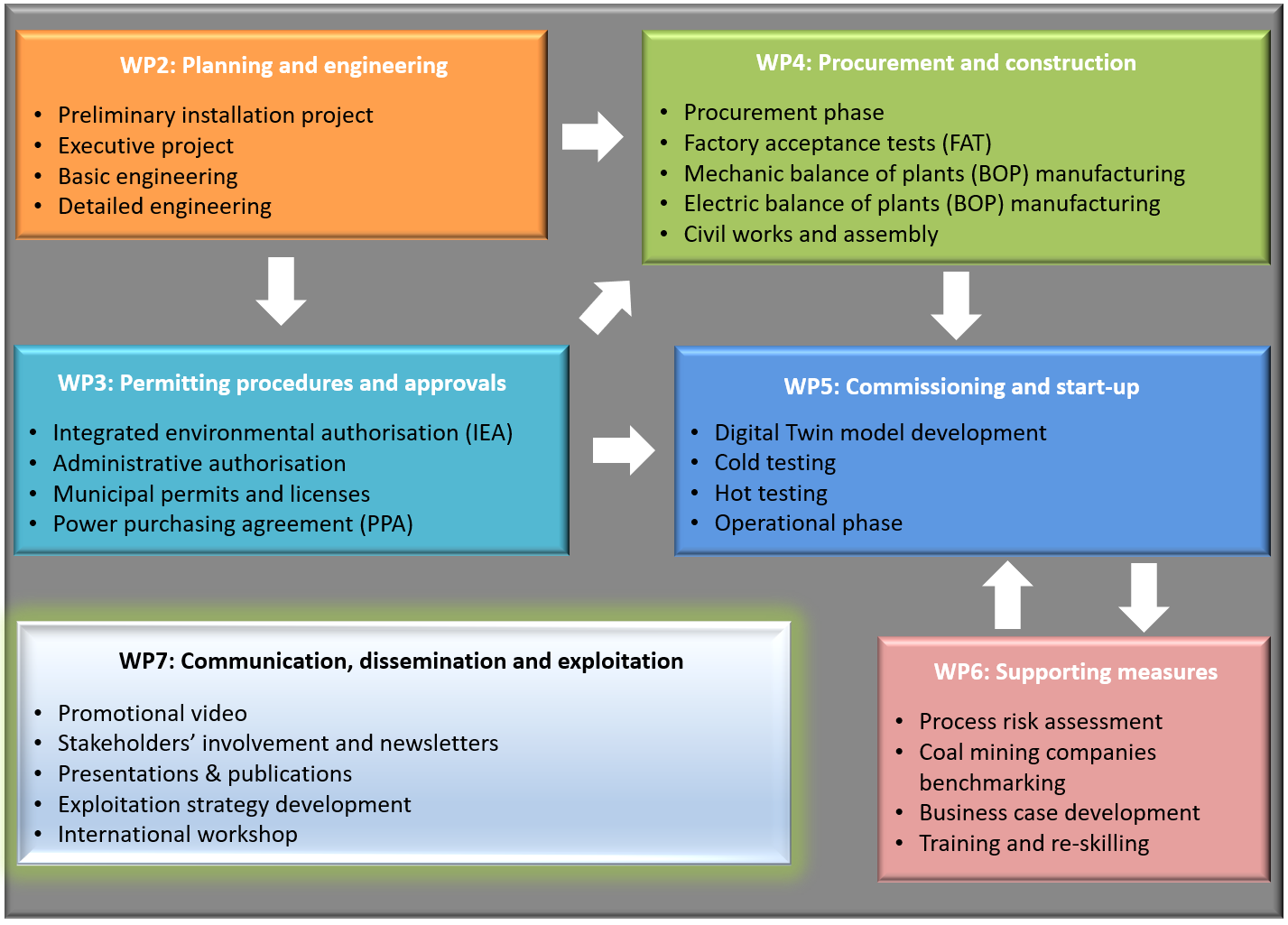

The proposal is structured into seven Work Packages to develop the project’s methodology:

This work package focuses on project coordination, including maintaining communication and collaboration among partners and with the European Commission. It involves organizing meetings, monitoring project deliverables, preparing and presenting reports, and addressing Just Transition challenges. Additionally, it outlines the creation of a Consortium Agreement for intellectual property rights protection and a steering committee with representatives from each consortium beneficiary. The package also includes the design and upkeep of the project website.

This work package unfolds in three strategic phases to evolve the project’s infrastructure from concept to completion. It starts with the Preliminary and Executive Project phase, advancing the conceptual design into actionable engineering documents, optimizing layouts, and initiating environmental assessments. The subsequent Basic Engineering phase delineates the technical framework, essential for obtaining necessary permits. The final Detailed Engineering phase hones these designs, ensuring they’re ready for procurement and execution, culminating in comprehensive commissioning and performance testing. Leadership and collaboration across these phases are structured to leverage the strengths of DURO FELGUERA, HUNOSA, and NORTEGAS.

Work package 3 is intricately designed to navigate the regulatory landscape essential for the project’s realization, highlighting a multi-tiered approach towards securing environmental, administrative, and municipal approvals. It kickstarts with the Integrated Environmental Authorization (IEA) process, embodying the project’s commitment to sustainability by ensuring compliance with Spain’s environmental laws. This phase is collaborative, with pivotal roles played by DURO FELGUERA, HUNOSA, and NORTEGAS, emphasizing the importance of an environmental impact report and public engagement. Subsequent tasks delve into obtaining Administrative Authorization and Municipal Permits & Licenses, showcasing a comprehensive strategy to liaise with regional and national bodies, ensuring the project aligns with local urbanistic norms and secures the green light for construction.

The Power Purchasing Agreement (PPA) task underscores the project’s dedication to green energy, balancing the electricity needs of hydrogen production with renewable sources, marking a significant stride towards environmental sustainability and regional economic revitalization.

Work package 4 meticulously orchestrates the procurement, evaluation, and assembly processes for pivotal components and infrastructure. It begins with the tendering for essential equipment based on advanced engineering insights, progressing to meticulous factory tests to assure functionality and performance. This phase intricately assembles both mechanical and electrical systems, harmonizing with the project’s technological and sustainability goals. Concurrently, civil works ensure the hydrogen plant’s integration enhances existing utilities without disruption, supplemented by a strategically planned solar photovoltaic plant to bolster green energy supply, demonstrating a comprehensive approach to sustainable development.

Work package 5 initiates with the innovative development of a Digital Twin, employing advanced software for comprehensive simulation and integration with the district heating system. It meticulously progresses through cold testing to assess system functionality in a static state, followed by hot testing under operational conditions, ensuring each system performs optimally alone and in conjunction. The culmination in the operational phase focuses on maintenance, efficiency, and compliance, underpinning the project’s commitment to operational excellence and sustainability, with strategic collaboration among key partners to optimize performance and address future work packages.

Work package 6 is an intricate blend of risk assessment, industry benchmarking, business strategy development, and workforce transformation. It scrutinizes the green hydrogen plant’s processes for potential risks, particularly in hydrogen management, employing a Digital Twin for scenario analysis. It benchmarks against coal mining companies to evaluate the replicability of converting mines into green hydrogen facilities, considering technological, operational, and economic facets. A business case will be crafted, aiming to inspire similar transitions across the mining sector. Finally, it addresses the re-skilling of former coal miners, ensuring they are equipped for roles in renewable energy, signifying a holistic approach to sustainable industry transformation and workforce development.

Work package 7 meticulously orchestrates outreach and engagement strategies to amplify the project’s visibility and impact. This includes crafting and disseminating promotional materials, fostering stakeholder collaboration, and showcasing the project’s innovations through presentations, publications, and targeted demonstrations. It strategically positions the project as a pioneering green hydrogen initiative, leveraging workshops and digital platforms to share insights, facilitate industry transitions, and champion renewable energy solutions within and beyond the coal mining community.