Mine-to-H2 project is focused on…

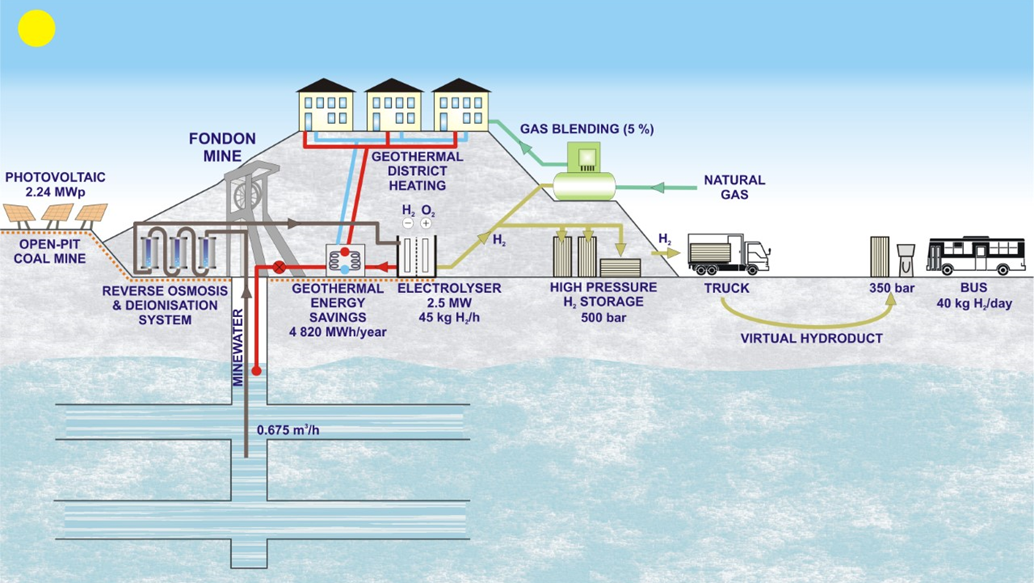

repurposing the former coal mine “Pozo Fondón” in Langreo (Asturias, Spain) through a 2.5 MW Green Hydrogen Plant, scalable up to 5 MW, where green hydrogen for the passenger road transport sector will be produced using circular economy actions: by electrolysis of mine water, and with electricity from a photovoltaic installation located in a former open-pit coal mine, as well as other renewable sources through a Power Purchase Agreement (PPA).

Project aim

Mine-to-H2 wants to demonstrate the feasibility of repurposing a former coal mine to produce green hydrogen using circular economy principles and coupling it with the heating sector. This involves establishing a green hydrogen plant in the “Pozo Fondon” coal mine in Langreo (Asturias, Spain), with the capacity to supply green hydrogen for road transport, hybridizing with existing geothermal facilities, injecting hydrogen into the natural gas grid, and providing training programs for former coal miners in renewable energy. The overarching goal is to contribute to the decarbonization of key sectors and promote the transition to a more sustainable and environmentally friendly economy.

Our approach

The green hydrogen produced by Mine-to-H2 will be stored in 500 bar pressure cylinders. It will be transported in trucks (virtual hydroduct) to a hydrogen refuelling station at 350 bar built for intercity buses with fuel cell technology, helping to decarbonise passenger transport by road. The project includes testing and demonstration in real conditions of an intercity bus, which CaetanoBus is currently developing using Toyota fuel cell technology, to connect the most important and populated cities of Asturias: Oviedo, Gijón and Avilés. In addition, the Green Hydrogen Plant will be coupled to the heating sector in two ways: (1) by blending part of the hydrogen into the existing natural gas grid; and (2) by hybridising with the existing geothermal facility at “Pozo Fondon”, improving the energy efficiency of the whole system by employing a new waste heat recovery process through the cooling of the electrolyser.